We offer our clients all the necessary services to be able to realize their facade with aluminum composite panel.

When it comes to construction and architectural projects, composite panel is a popular choice due to its high resistance to external weather conditions, corrosion and aging. However, to achieve the desired shape, the composite panel requires machining. Join us as we explore the world of composite panel machining.

The composite panel is a versatile and durable material that provides excellent protection against corrosion and weather conditions. With the various machining options and services offered by our specialized company, it is possible to create customized structures for construction and architectural projects. The cost of machining is reasonable and depends on the complexity of the work required. In general, the composite panel is a reliable and cost-effective solution for creating durable structures.

The use of CNC machinery or portable wall saw/milling machine allows for straight, curved and angled cuts, providing flexibility in design. With its balance of stiffness and flexibility, high resistance to corrosion, weathering and aging, and low cost per square meter, the composite panel is an excellent choice for any project requiring a reliable and cost-effective material. Its variety of finishes and formats, including solid, opaque and metallic colors, makes it even more attractive to architects, builders and designers who wish to add a touch of elegance and functionality to their projects.

Cutting can be performed in:

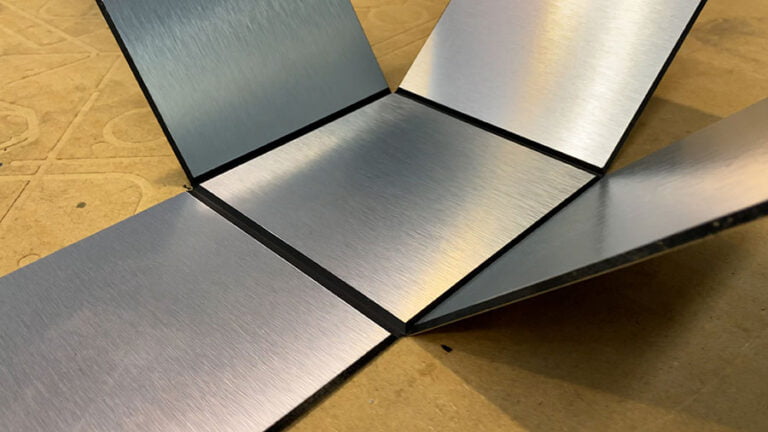

To fold a composite panel, perimeter flanges must be machined by partial milling of the panel, which are then bent and fixed with aluminum plates that are attached to the tray with rivets. This process must be carried out on a clean surface to avoid damaging the panel, which must wear its protective plastic at all times.

With this method it is possible to make folds with relief or 3D.

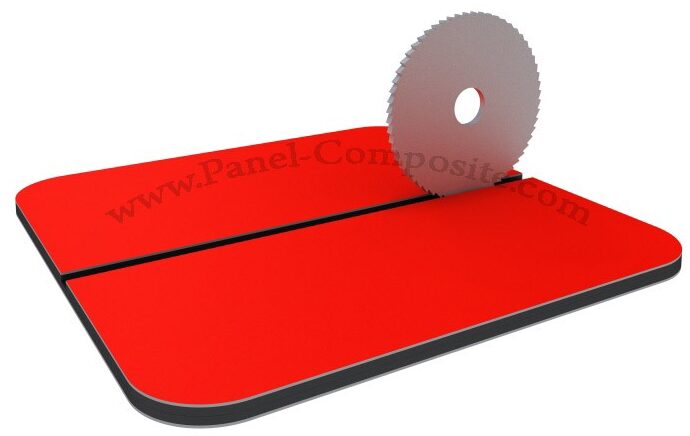

The milling of composite panels allows the parts to be subsequently bent. It can be done on CNC, with a wall saw, with a milling disc or with a portable milling machine. These tools should be milled at 90º or 135º, depending on the type of bend required. To bend the pieces there are specific tools and bending machines for composite panels, although they can also be bent by hand. When bending the composite panel parts, the fold should be in the center of the milling to ensure that the dimensions are as desired.

Our company offers different services and products related to the construction sector. Thanks to our variety we can offer different constructive resolutions to your most special needs.

131 Palauet Street

Catalunya – Lleida – 25001

Email: info@starmodul.com

Tel: +34 973 22 81 64

Mobile: +34 683 442 608

¿Necesitas ayuda?